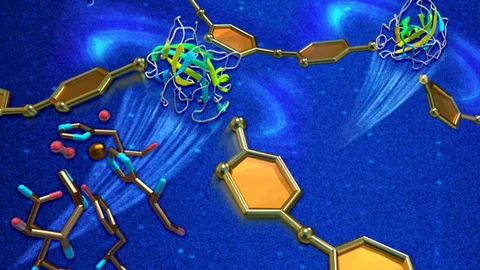

Industrial enzyme production is a fascinating intersection of biology and technology that plays a pivotal role in modern industries.

From fermentation processes to purification, this intricate journey transforms laboratory discoveries into mass-produced enzyme products that serve multiple sectors such as food and beverage, household care, biofuels, and more.

This comprehensive guide delves into the science behind industrial enzyme production, highlighting key applications and offering insights into strategic manufacturing models.

The Enzyme Production Journey

The journey an enzyme takes from the lab to large-scale production is complex and multifaceted. Known as industrial enzyme production, this process is not merely a matter of scaling up; it requires expertise in microbiology, biochemistry, and process engineering.

The primary challenge lies in producing quantities of enzymes while ensuring their activity, stability, and purity. These attributes are crucial for the enzymes to be cost-effective and reliable for use across diverse applications.

Step-by-Step Overview of the Production Process

Industrial enzyme manufacturing is a carefully structured, multi-stage pipeline designed for large-scale consistency.

The process begins with strain development, where a robust microbial host, such as Bacillus bacteria or Pichia yeast, is genetically modified to become a dedicated protein factory.

This is followed by fermentation, where these engineered cells are cultivated under meticulously controlled conditions in bioreactors ranging from small laboratory flasks to large production-scale fermenters that can exceed 100,000 liters.

Managing critical factors like oxygen transfer, nutrient distribution, and temperature becomes essential at this scale. The goal is to optimize these parameters to maximize enzyme yield.

Once fermentation is complete, the enzyme must be isolated through downstream processing, which consists of several important steps:

- Separation: Cells are removed from the fermentation broth using methods such as centrifugation or microfiltration.

- Purification: Techniques like ultrafiltration and chromatography are employed to isolate the target enzyme from other proteins and media components, achieving the required purity.

- Formulation: The final product is stabilized using additives or through lyophilization (freeze-drying), ensuring consistent activity and extending shelf life.

Key Applications of Industrial Enzymes

The rigorous production process ensures that enzymes serve as essential biocatalysts across various industries:

1. Food & Beverage

Enzymes play a crucial role in enhancing food quality and processing efficiency. For instance, amylases are employed in baking and brewing, proteases aid in cheese maturation, and pectinases are used for juice clarification. These enzymes improve texture, yield, and flavor profiles in food products.

2. Household Care

In modern detergents, enzymes such as proteases and lipases are integral components. These enzymes allow for effective cleaning at lower temperatures, contributing to environmental sustainability by reducing energy consumption.

3. Biofuels

In the realm of biofuels, enzymes such as cellulases and hemicellulases are vital for breaking down lignocellulosic biomass into fermentable sugars. This step is foundational in the production of second-generation bioethanol.

4. Animal Nutrition

Enzymes like phytase are commonly added to the feed of monogastric livestock, improving phosphorus bioavailability. This not only supports better animal growth but also mitigates phosphate pollution from manure.

5. Life Sciences

High-purity enzymes are essential tools in various life science applications, including molecular biology and diagnostics. For example, polymerases are used in PCR, while specialized biocatalysts are essential for synthesizing chiral pharmaceutical intermediates.

Strategic Pathways to Commercial Scale

Bringing a newly developed enzyme from the laboratory to the marketplace involves careful strategic planning regarding manufacturing capabilities.

Many organizations, particularly those focused on research and innovation, find that establishing in-house production facilities is prohibitively expensive, considering the substantial capital investment required for specialized infrastructure and resources.

This situation has led to the widespread adoption of the contract development and manufacturing organization (CDMO) model.

In-House vs. CDMO Partnership

Here’s a comparative overview of the core considerations when choosing between in-house development and partnering with a specialized CDMO:

| Consideration | In-House Development | Partnership with CDMO |

|---|---|---|

| Capital Investment | Very high due to facility setup. | Primarily operational expenditure, with minimal upfront costs. |

| Time to Market | Extended due to infrastructure development. | Accelerated by utilizing existing operational infrastructure. |

| Technical Expertise | Needs to be recruited internally. | Accessed through the partner’s core services. |

| Financial & Technical Risk | Entirely borne by the innovator. | Shared and mitigated by the CDMO’s experience. |

| Strategic Focus | Resources spread between R&D and manufacturing. | Enables focused resource allocation on core research and commercialization. |

This model reduces risk for innovators and facilitates a more streamlined path to market, offering essential expertise, established manufacturing protocols, and adherence to regulatory quality standards (such as cGMP for pharmaceuticals).

Future Outlook and Key Considerations

The industrial enzyme production landscape is continually evolving, influenced by advancements in synthetic biology and continuous bioprocessing. Companies entering this field should focus on several vital aspects from the onset:

- Scalability: Evaluate production scalability early in development; what works in the lab may not translate to industrial-scale fermentation.

- Specifications: Clearly define the required purity, activity, and formulation of the final product based on its intended industrial application.

- Regulatory Pathway: Familiarize yourself with the regulatory landscape early, especially for enzymes used in food, feed, or pharmaceuticals, as these sectors face stringent safety and quality standards.

Ultimately, industrial enzyme production serves as a crucial link that transforms potent biological catalysts into sustainable and efficient solutions for various industrial processes.

This not only supports businesses but also reinforces the role of enzymes as key tools in the global bioeconomic, promoting a healthier and more sustainable future.

As the demand for eco-friendly and efficient processes continues to rise, the importance of industrial enzymes will only grow, paving the way for innovative applications across all sectors of society.