Manufacturing today is far more advanced than it was even a decade ago. With the rise of automation, CNC technology, and digital workflows, employers are no longer looking only for machine operators.

They want skilled professionals who understand how a product moves from concept to completion. This is why blueprint reading training and CAD skills have become essential in modern manufacturing environments.

From CNC machining and aerospace to automotive and industrial fabrication, these skills form the foundation of accuracy, efficiency, and quality.

For individuals enrolled in skilled trades programs in Mississauga and across Ontario, developing both traditional and digital competencies is now a critical part of career readiness.

Blueprint Reading: The Language of Manufacturing

Blueprints are the primary communication tool used in manufacturing. They define a part’s dimensions, tolerances, materials, surface finishes, and assembly requirements.

Without strong blueprint interpretation skills, even the most advanced machinery cannot produce accurate results.

Proper blueprint reading training teaches machinists and technicians how to interpret symbols, geometric dimensioning and tolerancing (GD&T), views, and notes. These details directly affect how a part is machined and inspected.

A minor error—such as misreading a tolerance or datum—can result in rejected parts, material waste, and production delays.

In industries where precision is critical, such as aerospace, medical devices, and automotive manufacturing, blueprint accuracy is non-negotiable.

Skilled professionals who can confidently read and interpret drawings help maintain quality standards and reduce costly rework.

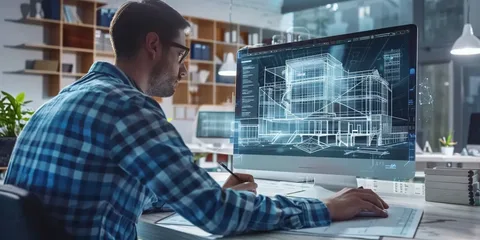

CAD Skills and Digital Manufacturing

While blueprints remain essential, modern manufacturing increasingly relies on digital design tools. Computer-Aided Design (CAD) software allows engineers and designers to create detailed 2D and 3D models that guide production.

For shop-floor professionals, CAD knowledge offers a deeper understanding of part geometry and design intent.

CAD training in Mississauga and other manufacturing hubs focuses on helping learners visualize complex components, understand tolerances in a digital environment, and recognize potential design challenges before machining begins.

CAD skills also improve collaboration. Machinists who understand CAD models can communicate more effectively with engineers and CNC programmers, leading to smoother workflows and fewer misunderstandings.

This shared digital language helps bridge the gap between design and production.

The Connection Between CAD and CNC Machining

In CNC environments, CAD skills naturally extend into CAM (Computer-Aided Manufacturing). CAM software uses CAD models to generate toolpaths and machining strategies.

Professionals who understand the design side of a part are better equipped to optimize machining processes.

This is why many CNC machining programs now emphasize both blueprint interpretation and CAD fundamentals.

When machinists understand how a part was designed, they can make better decisions about tooling, setups, feeds, and speeds. This results in improved efficiency, reduced cycle times, and higher-quality parts.

As CNC machines become more advanced, the demand for digitally skilled operators and programmers continues to grow.

Reducing Errors and Improving Efficiency

One of the greatest advantages of combining blueprint reading and CAD skills is error prevention. When professionals can cross-check a blueprint against a digital model, inconsistencies and potential issues can be identified early.

This proactive approach reduces scrap, protects expensive equipment, and improves overall productivity. In competitive manufacturing environments, even small efficiency gains can make a significant difference.

Employers increasingly value candidates who bring both technical accuracy and digital awareness to the shop floor.

Meeting Ontario’s Manufacturing Workforce Needs

Ontario remains one of Canada’s strongest manufacturing regions, supported by investments in automation, advanced machining, and smart factories. As technology evolves, so do workforce expectations.

Employers now look for graduates of CNC training in Ontario who are comfortable working with drawings, CAD software, and CNC equipment.

Training models that combine classroom instruction with hands-on experience better reflect real-world manufacturing conditions.

In areas like Mississauga and the Greater Toronto Area, skilled trades programs that align with industry needs play a key role in developing job-ready talent for local manufacturers.

Career Benefits for Skilled Trades Professionals

For individuals pursuing manufacturing careers, blueprint reading and CAD skills open doors to a wider range of opportunities.

These skills are often required for roles such as CNC operator, CNC programmer, setup technician, quality inspector, and manufacturing technologist.

Graduates of skilled trades programs in Mississauga who possess both traditional trade skills and digital competencies are often more competitive in the job market. They tend to advance more quickly and adapt more easily to new technologies and processes.

As automation continues to reshape manufacturing, workers who can think critically, read designs accurately, and understand digital tools remain in high demand.

Preparing for the Future of Manufacturing

Manufacturing is no longer about repetitive tasks—it is about precision, problem-solving, and collaboration.

Blueprint reading and CAD skills empower professionals to take on greater responsibility, contribute to process improvements, and adapt as technologies change.

Across Ontario, industry-aligned training environments are recognizing this shift. Programs that integrate blueprint reading training, CAD instruction, and hands-on CNC experience help learners transition smoothly into modern manufacturing roles.

This balanced approach ensures that graduates are not only technically capable, but also adaptable and future-ready.

Conclusion

Blueprint reading and CAD skills are essential pillars of modern manufacturing. Together, they improve accuracy, reduce errors, enhance collaboration, and support efficient production workflows.

As manufacturing continues to evolve through automation and digitalization, professionals who master both skills will remain valuable assets to employers.

For anyone considering a career in CNC machining or advanced manufacturing, developing these competencies through practical, industry-aligned training is a vital step toward long-term career success.