Introduction

Silicone surfactants occupy a pivotal position in the evolving landscape of global specialty chemicals, driven largely by advancements in personal care, polyurethane foam, textiles, and agriculture. Characterized by their unique hydrophobic backbone and organosilicon polar groups, these substances are shaping product performance and manufacturing standards across multiple industries. Examining the market’s growth, segment trends, and regional dynamics reveals why silicone surfactants have become indispensable to industrial innovation.

What Are Silicone Surfactants?

Silicone surfactants are unique chemicals that help mix water and oils, reduce surface tension, and improve spreading and wetting properties. Unlike traditional surfactants, silicone-based ones have a silicone backbone, which gives them special qualities such as heat resistance, flexibility, and smoothness. These features make silicone surfactants popular in many industries, especially where performance and quality matter.

Key Drivers of the Silicone Surfactant Market

1. Growing Demand in Personal Care and Cosmetics

One of the biggest uses of silicone surfactants is in personal care products like shampoos, conditioners, lotions, and makeup. Consumers want products that feel smooth, work well, and last long. Silicone surfactants help deliver these benefits by improving texture and spreadability. As people become more aware of beauty and self-care, the demand for such products keeps rising, boosting the market.

2. Expansion in Agricultural Applications

Silicone surfactants are also widely used in agriculture. They help pesticides and herbicides spread evenly on plants, improving their effectiveness. This means farmers can use less chemical while getting better results, which is good for the environment and cost-saving. As food production grows to meet global needs, the use of silicone surfactants in agriculture is expected to increase.

3. Industrial and Household Cleaners

Cleaning products, both industrial and household, benefit from silicone surfactants. These chemicals help detergents work better by breaking down dirt and grease faster and improving rinsing. The growing awareness of hygiene and cleanliness around the world is creating more demand for high-performance cleaning products, which in turn supports the silicone surfactant market.

4. Technological Advancements and Innovation

New research and development have led to improved silicone surfactants that are more effective and environmentally friendly. Innovations focus on creating products with lower toxicity and better biodegradability, meeting stricter regulations. This makes silicone surfactants attractive for industries aiming to produce safer and greener products.

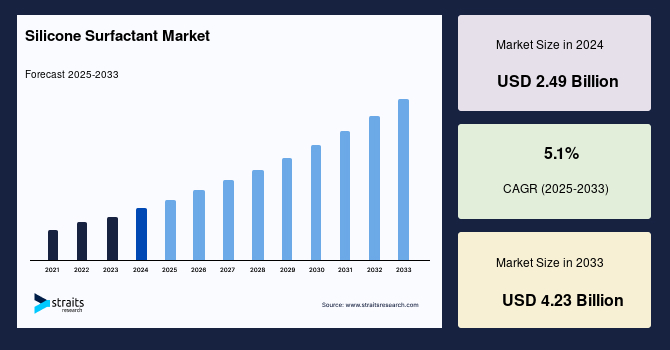

Market Growth and Outlook

The global silicone surfactant market size was valued at USD 2.49 billion in 2024 and is estimated to grow from USD 2.66 billion in 2025 to reach USD 4.23 billion by 2033, growing at a CAGR of 5.1% during the forecast period (2025-2033). The growth of the market is attributed to growing personal care industry and increasing demand for polyurethane foams.

Chemistry and Functional Versatility

Silicone surfactants are known for their stability and water-repelling properties, thanks to the polydimethylsiloxane backbone and their complex, high molecular weight structures. This unique chemistry allows them to work well at low temperatures, making them useful in many industrial settings. They are used in a variety of applications, such as foam leveling in polyurethane foams, emulsifiers, wetting agents, defoamers, antistatic agents, and even fuel additives. They are especially good at reducing surface tension, being low in toxicity, preventing foam, and providing consistent performance, showcasing their versatility.

Nonionic silicone surfactants are the most common, valued for their ability to mix well with anionic surfactants, stable performance, and skin- and eye-friendly nature. They also have antibacterial properties and remain stable in alkaline solutions, making them ideal for high-performance products, particularly in personal care and hygiene.

Drivers from Personal Care and Polyurethane Foam Industries

Personal care remains a key driver of surfactant demand, with silicone surfactants being vital in products like shampoos, conditioners, body washes, soaps, and skincare. They offer important functions such as foaming, emulsifying, dispersing, conditioning, and solubilizing, which improve product quality and sensory experience. As innovation grows and disposable incomes rise, new products are being developed, boosting the use of specialty surfactants.

At the same time, the growing construction sector increases the need for polyurethane foams in insulation and structural applications. As urbanization speeds up, silicone surfactants help improve foam quality, making these materials more suitable for energy-efficient and regulation-compliant building solutions.

Challenges and Constraints

Despite strong growth, the market faces challenges, mainly due to limited demand for oil-soluble silicone surfactants. These types aren’t ideal for all skin types and tend to be less effective than water-soluble versions, especially in areas where high absorption and emulsification are needed. Other challenges include complex regulations, competition from other technologies, performance issues, raw material price fluctuations, and environmental concerns.

In contrast, water-soluble silicone surfactants are more widely used and accepted, especially in personal care, agriculture, and textiles. Their ability to improve emulsification and stabilize foam makes them more popular in these industries.

Opportunity: The Textile Industry

Textile manufacturing is emerging as a growth lever for silicone surfactant applications. Enhancing product quality, dye dispersion, and end-product performance, these surfactants facilitate better processing and improve characteristics such as softness, color retention, and durability. As demand for textiles rises in emerging economies, the necessity for processing aids like silicone surfactants escalates, offering substantial opportunities for market penetration and expansion.

Regional Landscape

Asia-Pacific leads the global silicone surfactant industry, thanks to strong chemical manufacturing, a growing personal care market, and fast urban growth. Government policies in countries like China and India encourage local chemical production and boost the market. Innovations in eco-friendly silicone surfactants, especially in Japan and South Korea, are opening new growth opportunities. Textile and personal care products are very popular in Southeast Asia, where consumer demand and industrial growth keep rising.

North America is close behind, showing strong growth due to new technologies and a big focus on research and development. The region is known for creating special surfactants used in oil and gas recovery, high-quality coatings, and farming aids. Its solid supply chain and major silicone manufacturers give North America a competitive advantage. Industries like automotive and aerospace are driving more demand for customized surfactant products, keeping the market active.

Application Segmentation and End-Use Analysis

In the silicone surfactant industry, emulsifiers are the biggest segment. They help keep oil and water mixed in products like personal care items, agricultural chemicals, and industrial goods. These emulsifiers improve the feel of the product, help spread active ingredients evenly, and make products last longer, raising the quality of consumer goods.

Wetting agents are important for helping liquids spread and soak in better. This is useful in farming for applying pesticides, in dyeing fabrics, and in industrial coatings. Silicone surfactants are especially good at lowering surface tension, making them important additives in many processes.

Looking at who uses these products, agriculture is the top industry. Silicone surfactants help improve pesticide performance and protect crops by helping liquids spread and absorb better, leading to higher yields and healthier crops. The personal care industry is also important, as silicone surfactants play a big role in making conditioning, foaming, and feel-good products.

Looking Forward: Market Prospects

Entering a new era of chemical innovation, silicone surfactants are positioned to lead the transformation of personal care, construction, textile, and agricultural sectors. Growth prospects will depend on continued research, the launch of sustainable formulations, and the industry’s agility in responding to consumer and regulatory demands. Manufacturers who capitalize on the expanding base of industrial applications and emerging geographic opportunities will be best placed to capture share in this dynamic market.

Read More: https://worldwidedigest.com/networking-strategies-for-success/