Metro rail systems are expanding rapidly across major cities in India and across the globe. With rising urban populations, increasing passenger density, and growing expectations for sustainable infrastructure, metro coaches must be built using materials that offer durability, safety, and long-term value.

From underground tunnels exposed to moisture to elevated corridors facing pollution and extreme weather, rolling stock materials must withstand harsh operating conditions every day. In this environment, stainless steel has emerged as the preferred material for modern metro rail coaches. It offers the right combination of structural strength, corrosion resistance, safety performance, and lifecycle efficiency.

This blog explains why chromium steel metro coaches dominate modern rail manufacturing and why chromium steel railway components are widely used in today’s metro systems.

Evolution of Materials in Metro Coach Manufacturing

Mild Steel in Early Railway Coaches

In the early years of rail transport, mild steel was commonly used for coach construction. While it provided reasonable structural strength, it required frequent maintenance due to rust and corrosion. Regular repainting and structural repairs increased long-term operational costs.

Aluminum as a Lightweight Alternative

To reduce overall train weight and improve energy efficiency, aluminum was later introduced in rail coach manufacturing. Although aluminum reduced mass, it has certain limitations:

- Lower fatigue strength under repetitive loading

- Higher susceptibility to dents and deformation

- Limited performance under high-impact stress

Transition to Stainless Steel

Over time, manufacturers began adopting chromium steel metro coaches because of their superior mechanical properties and durability. Stainless steel combines strength, corrosion resistance, and long service life, making it more suitable for demanding metro environments.

High Strength-to-Weight Ratio

One of the main reasons stainless steel is preferred in metro rail manufacturing is its excellent strength-to-weight ratio. Advanced chromium steel grades such as 200 series, 300 series, 400 series, and duplex variants provide:

- High tensile strength

- Strong fatigue resistance

- Structural stability

- Reduced thickness without compromising safety

This allows engineers to design lightweight yet strong metro coach bodies capable of handling high passenger density and operational stress.

Structural elements such as underframes, side walls, and roof panels benefit significantly from stainless steel’s strength characteristics. The material ensures long-term reliability without adding unnecessary weight.

Superior Corrosion Resistance

Metro trains operate in challenging environments that can accelerate material degradation. These include:

- Underground tunnels with high humidity

- Coastal regions with salt exposure

- Industrial zones with airborne pollutants

- Frequent temperature variations

Stainless steel contains chromium, which forms a protective passive layer on the surface. This layer prevents rust and corrosion even under harsh environmental conditions.

Corrosion-resistant railway materials such as chromium steel significantly reduce maintenance requirements. This improves operational efficiency and ensures long-lasting metro coach durability.

Long Service Life and Lower Maintenance

Metro systems are long-term infrastructure investments. Coaches are expected to operate efficiently for several decades. Lifecycle cost becomes more important than initial material cost.

Stainless steel offers:

- Minimal repainting requirements

- Reduced corrosion-related repairs

- Extended service intervals

- Lower replacement frequency

Because chromium steel retains its structural integrity over time, metro operators benefit from reduced downtime and maintenance expenses. Over a 30–40 year operational period, stainless steel metro coaches often prove more economical than alternative materials.

Fire Resistance and Passenger Safety

Safety is a critical priority in metro rail systems. Materials used in coach construction must comply with strict fire safety and structural standards.

Stainless steel provides:

- High melting point

- Resistance to flame spread

- Structural stability during high-temperature exposure

In the event of fire incidents, chromium steel maintains its strength longer than many other materials. This enhances passenger protection and supports evacuation procedures.

Fire-resistant railway materials are essential for regulatory approvals, and chromium steel consistently meets these requirements.

Sustainability and Recyclability

Sustainability is increasingly influencing infrastructure decisions. Metro authorities aim to reduce environmental impact and improve material efficiency.

Stainless steel supports sustainable metro infrastructure in several ways:

- It is 100% recyclable

- It has an extended service life

- It reduces material replacement frequency

- It supports environmentally responsible manufacturing practices

At the end of a metro coach’s life cycle, chromium steel components can be recycled without losing their essential properties. This makes stainless steel an environmentally responsible choice for long-term urban transit systems.

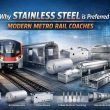

Applications of Stainless Steel in Metro Coaches

Stainless steel is widely used in both structural and functional components of metro coaches.

Structural Shell Components

- Side walls

- Roof panels

- Underframes

- Car body shells

Enclosures and Protective Housing

Metro coaches contain several mechanical and electrical systems that require protection, including:

- Battery boxes

- Air reservoirs

- Valve boxes

Stainless steel enclosures protect these systems from corrosion, physical damage, and environmental exposure.

Interior Fittings and Safety Elements

Passenger safety and comfort rely on durable interior fittings such as:

- Handrails

- Grab poles

- Cable ducts

- Seating frames

Stainless steel interior components resist wear caused by continuous passenger use. They also maintain a clean and professional finish over time.

Stainless Steel vs Aluminum in Metro Coaches

When comparing stainless steel and aluminium in metro coach construction, several factors must be evaluated.

Structural Strength

Stainless steel generally offers higher tensile and fatigue strength, making it more suitable for structural applications subject to repeated loading.

Corrosion Performance

Both materials resist corrosion, but stainless steel performs better in polluted, humid, and coastal environments without requiring protective coatings.

Lifecycle Cost

Although aluminum reduces weight, chromium steel often provides better long-term value due to lower maintenance and higher durability.

Maintenance Requirements

Stainless steel requires minimal repainting and surface treatment, reducing operational downtime.

For these reasons, many metro manufacturers prefer chromium steel for critical structural and safety components.

Importance of Certifications and Standards

Metro rail manufacturing operates under strict global standards to ensure safety and reliability.

Key certifications include:

- IRIS (International Railway Industry Standard)

- EN15085 welding certification

- ISO quality management systems

These certifications ensure consistent quality, proper welding procedures, material traceability, and structural integrity. Stainless steel railway components manufactured under certified systems provide greater confidence to metro authorities and rolling stock manufacturers.

Role of Advanced Fabrication and Testing

Precision engineering is essential in metro coach manufacturing. Stainless steel fabrication involves advanced processes such as:

- Robotic welding

- Fiber laser cutting

- CNC bending and forming

- Non-destructive testing

Each component undergoes thorough testing for:

- Tensile strength

- Corrosion resistance

- Weld integrity

- Dimensional accuracy

Advanced manufacturing capabilities ensure that stainless steel metro components perform reliably under real-world conditions.

Right Steel Metro Component Manufacturer

Material selection alone does not guarantee performance. The expertise and capability of the manufacturer play a critical role in ensuring compliance and reliability.

When selecting a stainless steel metro component manufacturer, decision-makers should evaluate:

- IRIS certification

- EN15085 welding compliance

- Production capacity

- In-house testing facilities

- Experience in metro and railway projects

- Capability to work with multiple stainless steel grades

Jindal Mobility specializes in stainless steel components for metro systems. With experience in manufacturing structural shells, enclosures, and interior fittings, the company supports metro projects from design and prototyping to mass production. Its certified processes, integrated facilities, and strong quality control systems make it a reliable partner for metro OEMs and system integrators.

Partnering with a qualified manufacturer reduces supply chain risks, ensures consistent quality, and supports the long-term success of metro projects.

Conclusion

Modern metro rail systems demand materials that deliver durability, safety, efficiency, and sustainability. Stainless steel meets these requirements effectively.

Its high strength-to-weight ratio, excellent corrosion resistance, long lifecycle performance, fire safety characteristics, and recyclability make it the preferred material for modern metro rail coaches.

From structural shells and underframes to interior fittings and protective enclosures, stainless steel railway components form the backbone of reliable urban transit systems. When combined with certified manufacturing processes and advanced fabrication technology, steel enables metro networks to operate safely and efficiently for decades.

As metro infrastructure continues to expand worldwide, steel will remain central to the future of rolling stock material innovation.