Behind every beautifully embroidered logo, jacket, or cap lies a hidden process that determines whether the final product will look professional or amateurish. That process is digitizing—the technical art of converting artwork into stitch instructions that embroidery digitizing machines can follow with precision.

Many people assume modern embroidery machines handle everything automatically. Insert an image, press a button, and perfect stitching emerges. This misconception leads to disappointment when results show gaps, puckering, or distorted shapes. The truth is simpler and more demanding: embroidery quality depends almost entirely on how well someone digitized the design before the machine ever touched fabric.

Understanding What Digitizing Actually Means

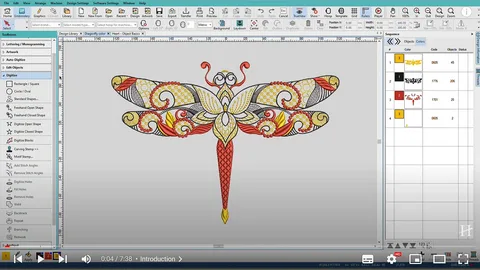

Digitizing transforms flat artwork into a language of stitches. When you look at a company logo or decorative design, your eyes see continuous shapes and colors. An embroidery machine sees nothing until someone translates that visual information into specific commands: stitch here in this direction, use this many stitches per inch, start from this point, end at that point.

This translation process requires far more than tracing an image with digital tools. Professional digitizers must understand how different fabrics respond to tension, how stitches interact with one another, and how thread behaves when pulled through various materials. They make dozens of microscopic decisions that collectively determine whether the finished embroidery looks crisp and professional or messy and unrefined.

The difference between automatic software conversion and professional manual digitizing becomes immediately obvious to anyone who examines embroidery closely. Automated results often show visible flaws—gaps between color sections, distorted lettering, uneven edges. Professionally digitized designs maintain their integrity because a skilled human made intentional choices about every stitch.

Why Custom Approaches Beat One-Size-Fits-All Solutions

Every embroidery project brings unique requirements. The fabric type alone dramatically changes how digitizers must approach a design. Dense canvas demands different treatment than stretchy polo shirt material. Delicate silk requires adjustments that heavy denim doesn’t need. Caps curve around three-dimensional forms, while flat garments present no such challenge.

A custom embroidery digitizing service accounts for digitizers don’t apply the same settings to every design. They analyze each project individually, considering the final application, the fabric characteristics, the design complexity, and the production environment.

This tailored approach prevents the common problems that plague embroidery production. When digitizing accounts for fabric stretch, the design doesn’t distort during stitching. When underlay stitches properly stabilize the surface, edges stay crisp instead of sinking into textured materials. When pull compensation accounts for thread tension, shapes maintain their intended proportions rather than narrowing or distorting.

The Technical Knowledge Behind Great Embroidery

Professional digitizers bring specialized knowledge that casual observers never see. They understand stitch types at a deep level—when to use satin stitches for smooth borders, when fill stitches work better for large areas, how running stitches can create delicate details. They know that changing stitch direction affects how light reflects from finished embroidery, influencing the design’s visual impact.

Stitch density represents another critical variable. Too few stitches, and the design looks thin and incomplete, with fabric showing through gaps. Too many stitches, and the embroidery becomes stiff and uncomfortable, potentially damaging delicate fabrics. Professional digitizers calculate optimal density based on thread weight, fabric type, and design requirements.

Underlay stitching might be the most invisible yet essential element of quality digitizing. These foundation stitches stabilize the fabric before the visible top stitches appear. They prevent shifting, reduce puckering, and create a smooth surface for detailed embroidery. Without proper underlay, even beautifully digitized designs can fail during production.

Pull compensation addresses how thread tension pulls fabric slightly as stitches form. Experienced digitizers anticipate this movement and adjust design dimensions accordingly. A circle digitized without pull compensation might emerge as an oval. Professional digitizing ensures shapes emerge as intended.

How Professional Services Improve Production Efficiency

For businesses running embroidery equipment, digitizing quality directly impacts bottom-line performance. Poorly digitized designs cause machine stoppages, thread breaks, and constant operator intervention. Each interruption costs time and money while increasing frustration.

Professional custom embroidery digitizing service providers deliver files that run smoothly through production. Machines operate continuously without constant adjustments. Thread consumption becomes predictable and efficient. Operator attention focuses on loading and unloading rather than troubleshooting design problems.

This efficiency extends to reorders and repeat business. Once professionally digitized, a design remains available for future production runs without additional investment. Companies can fulfill uniform programs, promotional merchandise orders, and corporate branding requests with consistent quality every time.

Matching Designs to Their Final Applications

Different embroidery applications demand different digitizing approaches. Understanding these distinctions separates adequate digitizing from exceptional work.

Corporate logos on employee uniforms require durability above all. These designs will face repeated washing and daily wear. Professional digitizing ensures stitches remain secure and edges stay crisp through months of use. The design maintains its professional appearance, reflecting well on the company throughout its lifespan.

Sports apparel presents different challenges. Athletic fabrics often stretch and move with the body. Digitizing must account for this flexibility, using techniques that allow the embroidery to move with the fabric rather than fighting against it. Moisture-wicking materials may require special backing choices and stitch adjustments.

Caps and hats demand specialized techniques due to their curved surfaces and structured construction. Digitizers must plan for the frame’s shape, adjusting designs to appear correct when worn rather than when viewed flat. Lettering around curved surfaces requires particular attention to maintain readability.

Jacket back designs showcase large-scale embroidery possibilities. These substantial pieces require careful planning to maintain efficiency while achieving visual impact. Stitch counts climb quickly with size, making optimization essential for both appearance and production cost.

Delicate fashion items call for the lightest touch. Fine fabrics cannot support heavy stitching. Professional digitizers adjust density, choose appropriate backings, and select stitch types that complement rather than overwhelm the base material.

The Value of Experience and Expertise

Choosing an embroidery digitizing company means selecting the expertise behind the files. Experienced digitizers have encountered countless design challenges and developed solutions through years of practice. They recognize potential problems before they occur and adjust designs accordingly.

This experience manifests in subtle ways that collectively determine quality. They know how small lettering requires special handling to remain readable. They understand which design elements need reinforcement at stress points. They anticipate how different thread types will behave during production.

Communication between digitizers and clients also matters significantly. Professional services discuss requirements thoroughly before beginning work. They ask about fabric types, production volumes, and final applications. This information gathering ensures the resulting files truly meet project needs rather than representing generic solutions.

Why Multiple File Formats Matter

Embroidery machines speak different languages. A file format that works perfectly on one brand of machine may be completely unusable on another. Professional digitizing companies understand this reality and provide files in the formats each client requires.

This flexibility simplifies production planning. Companies don’t need to convert files themselves, potentially introducing errors. They receive ready-to-run files that load directly into their specific equipment. Whether a business uses Tajima, Barudan, Melco, or other major machine brands, professional services deliver compatible formats.

The Long-Term Benefits of Professional Digitizing

Investing in quality digitizing pays dividends long after production completes. Well-digitized designs hold up through repeated use, maintaining their appearance for years. This durability matters enormously for branded merchandise, team uniforms, and corporate apparel that represent organizations publicly.

Production efficiency improves consistently when working with quality files. Machine operators spend less time troubleshooting and more time producing. Thread waste decreases. Tension problems diminish. The entire embroidery operation runs more smoothly.

Customer satisfaction naturally follows from quality results. When clients receive embroidered products that look professional and perform durably, they return with additional orders. Word spreads about reliable quality. The embroidery business builds reputation through consistently excellent output.

Finding the Right Partner for Your Embroidery Needs

The market offers many options for digitizing services, but quality varies dramatically. Low-cost providers often deliver exactly what their pricing suggests—minimally processed files that cause production problems and disappoint clients. Professional services charge appropriately for expertise that saves money overall through efficiency and quality.

Look for digitizing companies with demonstrated experience across diverse applications. They should understand fabric behaviors, machine capabilities, and design requirements thoroughly. Communication should be clear and responsive. Turnaround times should balance speed with quality—very fast delivery sometimes indicates rushed, careless work.

A reliable custom embroidery digitizing service stands behind its work. If production issues arise from the digitizing itself, the provider should address them promptly. This accountability matters enormously for businesses depending on consistent quality.

The Foundation of Embroidery Digitizing Excellence

Every piece of quality embroidery digitizing begins with proper digitizing. No amount of machine sophistication or operator skill can compensate for poorly prepared design files. The digitizing stage sets the ceiling for final quality—even the best execution cannot exceed what the file enables.

Understanding this reality transforms how businesses approach embroidery production. Rather than treating digitizing as an afterthought or expense to minimize, successful operations recognize it as the foundation upon which everything else builds. They invest in professional expertise because they understand that quality digitizing pays for itself many times over through efficiency, durability, and customer satisfaction.

Whether creating corporate branding, sports uniforms, fashion pieces, or promotional merchandise, the path to beautiful embroidery digitizing runs through skilled digitizing. The hidden work of converting artwork to stitches determines everything visible in the final product. When that work is done professionally, the embroidery speaks for itself.