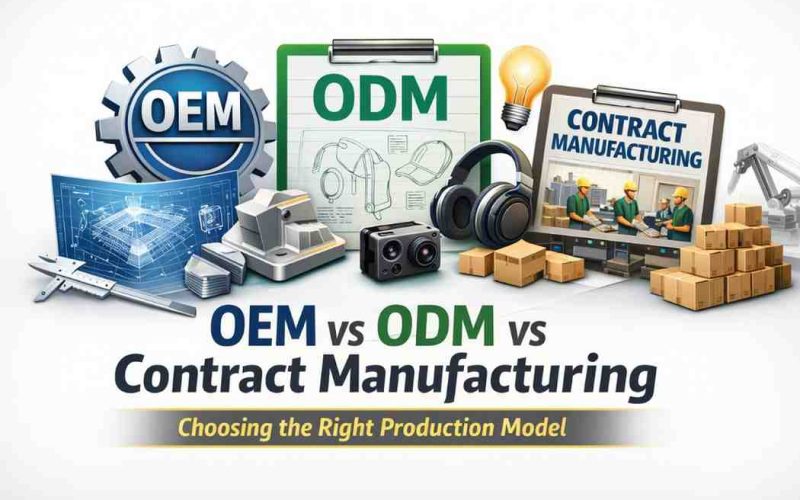

In manufacturing conversations, three production models surface again and again—OEM vs ODM, and contract manufacturing. They often get used interchangeably, which is where confusion begins. In reality, each model reflects a very different way of thinking about control, ownership, risk, and long-term brand value.

Choosing between them is less about labels and more about how a business wants to grow, protect its ideas, and manage its supply chain.

This distinction matters even more today. Markets move faster, product lifecycles are shorter, and customers expect both quality and consistency. The production model you align with quietly shapes everything from pricing power to innovation speed.

OEM: When design ownership sits with the brand

Original Equipment Manufacturing usually comes into play when a brand already knows exactly what it wants to build. The product concept, technical drawings, material specifications, and performance standards are defined by the brand itself.

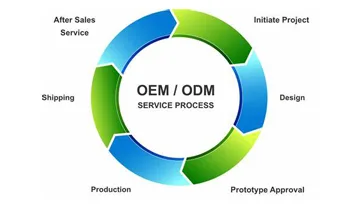

Manufacturing is entrusted to a specialized partner with the capability, scale, and process discipline to execute that vision accurately.

This model suits organizations that see design and engineering as core strengths. Automotive brands, industrial equipment companies, and premium homeware players often operate this way. The manufacturer’s role is execution—tooling, fabrication, assembly, quality control—without influencing the product’s identity.

Original Equipment Manufacturer relationships tend to be long-term. Once a manufacturer is integrated into the production ecosystem, switching partners is neither quick nor inexpensive. That commitment pays off in consistency and tighter quality control, especially for products that demand precision or compliance with strict standards.

The trade-off lies in responsibility. Design validation, performance accountability, and market fit remain firmly with the brand. If something fails in the field, the root cause may trace back to design decisions rather than production errors. OEM works best when internal teams are confident in their engineering depth and market understanding.

ODM: Speed and design efficiency under one roof

Original Design Manufacturing shifts the balance. Here, the manufacturer brings ready-made or semi-custom designs to the table. Brands select, adapt, and brand these products rather than building from a blank sheet.

This approach appeals to companies prioritizing speed-to-market. Consumer electronics, small appliances, lifestyle products, and private-label goods frequently rely on ODM partners. The heavy lifting—industrial design, prototyping, material selection—has already been done.

ODM reduces upfront development costs and shortens timelines, but it also narrows exclusivity. The same underlying design may appear in multiple markets with minor cosmetic changes. For brands focused on differentiation through storytelling, pricing, or distribution rather than technical novelty, that limitation is often acceptable.

Control is shared, not surrendered entirely. Reputable ODM partners allow modifications, material upgrades, and branding customization. Still, the core intellectual property usually remains with the manufacturer. That reality can influence long-term strategy, particularly if a product line becomes a major revenue driver.

Contract manufacturing: Capacity without ownership in OEM vs ODM

Contract manufacturing occupies a different space altogether. In this arrangement, the brand retains full ownership of design and intellectual property, while the manufacturer focuses strictly on production tasks. Sometimes this includes procurement and assembly; sometimes it extends to packaging and logistics.

This model is common in pharmaceuticals, FMCG, electronics assembly, and food processing. It works well for companies that want manufacturing flexibility without investing in facilities, labor, or machinery.

Unlike OEM, contract manufacturing does not imply design collaboration. The manufacturer follows instructions provided by the brand, often under strict confidentiality and compliance frameworks. The relationship can be short-term or seasonal, depending on demand cycles.

The main advantage is scalability. Production volumes can rise or fall without fixed overheads. The challenge lies in coordination. Since design and production are decoupled, any design changes require careful communication to avoid delays or inconsistencies.

Control, cost, and complexity: where the models diverge in OEM vs ODM

At a strategic level, the real differences between these models sit along three axes: control, cost structure, and operational complexity.

OEM offers maximum control over the product but demands higher internal investment in design and validation. ODM lowers development effort but limits exclusivity. Contract manufacturing reduces capital exposure while increasing dependency on process discipline and documentation.

Cost comparisons are rarely straightforward. ODM may appear cheaper upfront, yet margins can narrow when products lack differentiation. OEM can deliver better long-term value when volumes justify design investment. Contract manufacturing often looks attractive for variable demand but may carry higher per-unit costs at scale.

Complexity also shifts depending on the model. OEM relationships require deep technical alignment. ODM partnerships hinge on trust and transparency around design ownership. Contract manufacturing lives or dies by process clarity and quality oversight.

Choosing the right model for your business stage

Early-stage brands often gravitate toward ODM or contract manufacturing. Limited capital, lean teams, and urgent market entry make these models practical. As products gain traction, many companies reassess their approach, moving toward OEM arrangements to regain control and protect differentiation.

Mature organizations typically mix models across portfolios. Flagship products may follow OEM pathways, while accessories or seasonal lines rely on ODM or contract partners. This hybrid approach balances innovation with operational efficiency.

Industry context also plays a role. Regulated sectors lean toward OEM or tightly controlled contract manufacturing due to compliance requirements. Lifestyle and consumer goods brands priorities flexibility and speed, making ODM attractive.

The Indian manufacturing lens

In India, these models have taken on new significance. The push for domestic manufacturing, coupled with improving technical capabilities, has elevated Indian OEM partners across sectors such as stainless steel, mobility components, and industrial equipment.

Indian manufacturers increasingly offer OEM-plus capabilities—engineering support, material innovation, and process optimization—without crossing into full ODM territory. This middle ground appeals to global brands seeking reliability and cost efficiency without sacrificing design ownership.

Contract manufacturing has also matured locally, supported by better compliance systems and export-oriented infrastructure. For international brands, this has opened doors to scalable production with lower risk.

Long-term implications beyond production

The production model chosen today shapes tomorrow’s options. It influences supply chain resilience, negotiation leverage, and even brand perception. Customers may never see the factory floor, but they feel the outcome in product consistency, availability, and performance.

Shifts between models are possible, but rarely seamless. Moving from OEM vs ODM requires rebuilding design capability. Transitioning from contract manufacturing to OEM demands closer technical integration. These changes should be strategic, not reactive.

Making the decision with clarity

There is no universally superior model. The right choice aligns with business maturity, market ambition, and internal strengths. Companies that succeed treat production models as strategic frameworks rather than procurement decisions.

Clarity on ownership, accountability, and long-term goals prevents costly misalignment. Whether partnering for design execution, design acceleration, or pure production capacity, the most effective relationships are built on transparency and shared expectations.

In manufacturing, the quiet decisions often carry the loudest consequences. OEM, ODM, and contract manufacturing are not just operational choices—they are reflections of how a business sees its future.