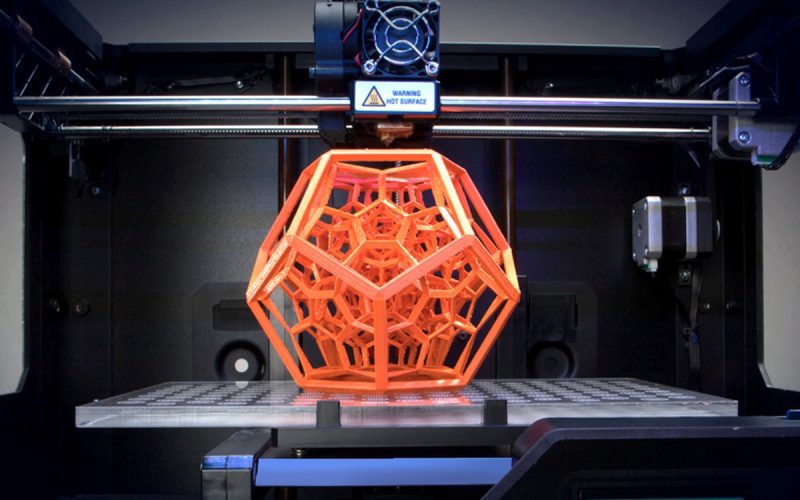

In recent years, 3D printing has emerged as a groundbreaking technology with the potential to revolutionize a myriad of industries, and healthcare is no exception. The advent of 3D printing in healthcare devices is transforming the way medical professionals diagnose, treat, and manage various health conditions. This article delves into the multifaceted ways in which 3D printing is reshaping the landscape of healthcare devices, providing insights into its benefits, applications, and future prospects.

The Rise of 3D Printing in Healthcare

3D printing, also known as additive manufacturing, involves creating three-dimensional objects from digital files by layering materials sequentially. This technology has been around since the 1980s, but its application in healthcare is a relatively recent phenomenon. The integration of 3D printing into healthcare devices has been driven by several factors, including advancements in printing materials, the increasing precision of 3D printers, and the growing demand for personalized medical solutions.

Personalized Healthcare Devices

One of the most significant advantages of 3D printing in healthcare is its ability to produce personalized devices tailored to individual patients’ needs. Traditional manufacturing methods often rely on mass production, which can result in generic devices that may not fit all patients perfectly. In contrast, 3D printing allows for the customization of medical devices based on precise anatomical data obtained from medical imaging technologies such as CT scans and MRIs.

For instance, prosthetics and orthotics can be custom-designed to match the exact dimensions of a patient’s limb, ensuring a better fit and increased comfort. This personalization not only enhances the functionality of the device but also improves patient outcomes and satisfaction.

Surgical Instruments and Models

3D printing has also made significant strides in the production of surgical instruments and models. Surgeons can now use 3D-printed models of patients’ anatomy to plan and practice complex procedures before performing them in the operating room. These models provide a tangible representation of the patient’s unique anatomy, allowing surgeons to visualize and rehearse the surgery with greater precision.

Moreover, 3D-printed surgical instruments can be designed to meet the specific requirements of a particular procedure. For example, custom-designed surgical guides can help ensure accurate placement of implants during orthopedic surgeries. This level of customization can lead to more efficient surgeries, reduced operative times, and improved patient outcomes.

Implants and Prosthetics

The development of 3D-printed implants and prosthetics represents one of the most promising applications of this technology in healthcare. Traditional implants, such as hip and knee replacements, are typically available in a limited range of sizes and shapes. However, 3D printing allows for the creation of implants that are tailored to the patient’s unique anatomy, resulting in a better fit and improved functionality.

In addition to standard implants, 3D printing has enabled the production of complex, patient-specific implants that were previously impossible to manufacture using traditional methods. For example, cranial implants for patients with skull defects can be precisely designed to match the contours of the patient’s skull, providing a seamless fit and reducing the risk of complications.

Prosthetics are another area where 3D printing has made a significant impact. Traditional prosthetic limbs can be expensive and time-consuming to produce, often requiring multiple fittings and adjustments. 3D printing streamlines this process by allowing for the rapid production of custom-designed prosthetics at a fraction of the cost. This accessibility is particularly beneficial for patients in developing countries, where access to affordable prosthetic care is limited.

Bioprinting and Tissue Engineering

One of the most exciting frontiers of 3D printing in healthcare is bioprinting, which involves the use of bioinks—composed of living cells and biomaterials—to create tissue-like structures. While still in its early stages, bioprinting holds the potential to revolutionize regenerative medicine and tissue engineering.

Researchers are exploring the use of bioprinting to create functional tissues and organs for transplantation. For example, scientists have successfully bioprinted skin, cartilage, and even small sections of heart tissue. While the creation of fully functional, transplantable organs remains a long-term goal, the progress made in bioprinting offers hope for patients awaiting organ transplants and those with tissue damage.

Cost-Effectiveness and Accessibility

The cost-effectiveness of 3D printing is another compelling reason for its adoption in healthcare. Traditional manufacturing processes often involve significant overhead costs, including molds, tooling, and labor. In contrast, 3D printing eliminates the need for these intermediate steps, allowing for the direct production of devices from digital designs. This reduction in production costs can lead to more affordable healthcare devices, making advanced medical care accessible to a broader population.

Furthermore, 3D printing enables decentralized manufacturing, allowing healthcare providers to produce devices on-site or in remote locations. This capability is particularly valuable in emergency situations or in areas with limited access to specialized medical equipment. For example, during the COVID-19 pandemic, 3D printing was used to produce personal protective equipment (PPE) and ventilator components, addressing critical shortages and saving lives.

Challenges and Future Prospects

While the potential of 3D printing in healthcare devices is immense, several challenges must be addressed to fully realize its benefits. Regulatory approval is a significant hurdle, as 3D-printed medical devices must meet stringent safety and efficacy standards. Ensuring the quality and consistency of 3D-printed products is also crucial, as variations in printing materials and processes can impact the performance of the final device.

Additionally, the integration of 3D printing into clinical practice requires investment in infrastructure, training, and education. Healthcare professionals must be equipped with the knowledge and skills to effectively utilize 3D printing technology and integrate it into patient care.

Despite these challenges, the future of 3D printing in healthcare devices looks promising. Ongoing research and development are likely to yield new materials, printing techniques, and applications, further expanding the possibilities of this technology. As 3D printing continues to evolve, it has the potential to transform healthcare by providing personalized, cost-effective, and accessible medical solutions.

Conclusion

In conclusion, 3D printing is revolutionizing healthcare devices by enabling the production of personalized, high-quality medical solutions. From custom prosthetics and implants to surgical instruments and bioprinted tissues, the applications of 3D printing in healthcare are vast and varied. While challenges remain, the continued advancement of this technology holds the promise of improved patient outcomes, reduced healthcare costs, and greater accessibility to advanced medical care. As we move forward, 3D printing is poised to play a pivotal role in shaping the future of healthcare.