Meet the Author:

Hi everyone! I’m Fred, a civil engineer who loves building things. Today, we’re going on an underground adventure to meet the incredible machines that carve out tunnels – the Tunnel Boring Machines (TBMs)! Buckle up, because we’re about to see how these engineering marvels munch their way through mountains!

Delving Deep: The Wonderful World of TBMs

Have you ever stared out the window of a train, gazing at the darkness that engulfs you as you enter a tunnel? It’s a strange sensation, a temporary descent into an unseen world. But how exactly are these tunnels created? The answer lies with some truly amazing machines known as Tunnel Boring Machines (TBMs). Often referred to as “moles” due to their burrowing capabilities, TBMs are the unsung heroes of the underground construction industry.

These colossal machines are responsible for carving out the tunnels that form the backbone of our modern infrastructure. From the bustling subway systems beneath our cities to the high-speed train lines that connect continents, TBMs play a crucial role in creating efficient and safe transportation networks.

Taking a Bite Out of Rock: How TBMs Work

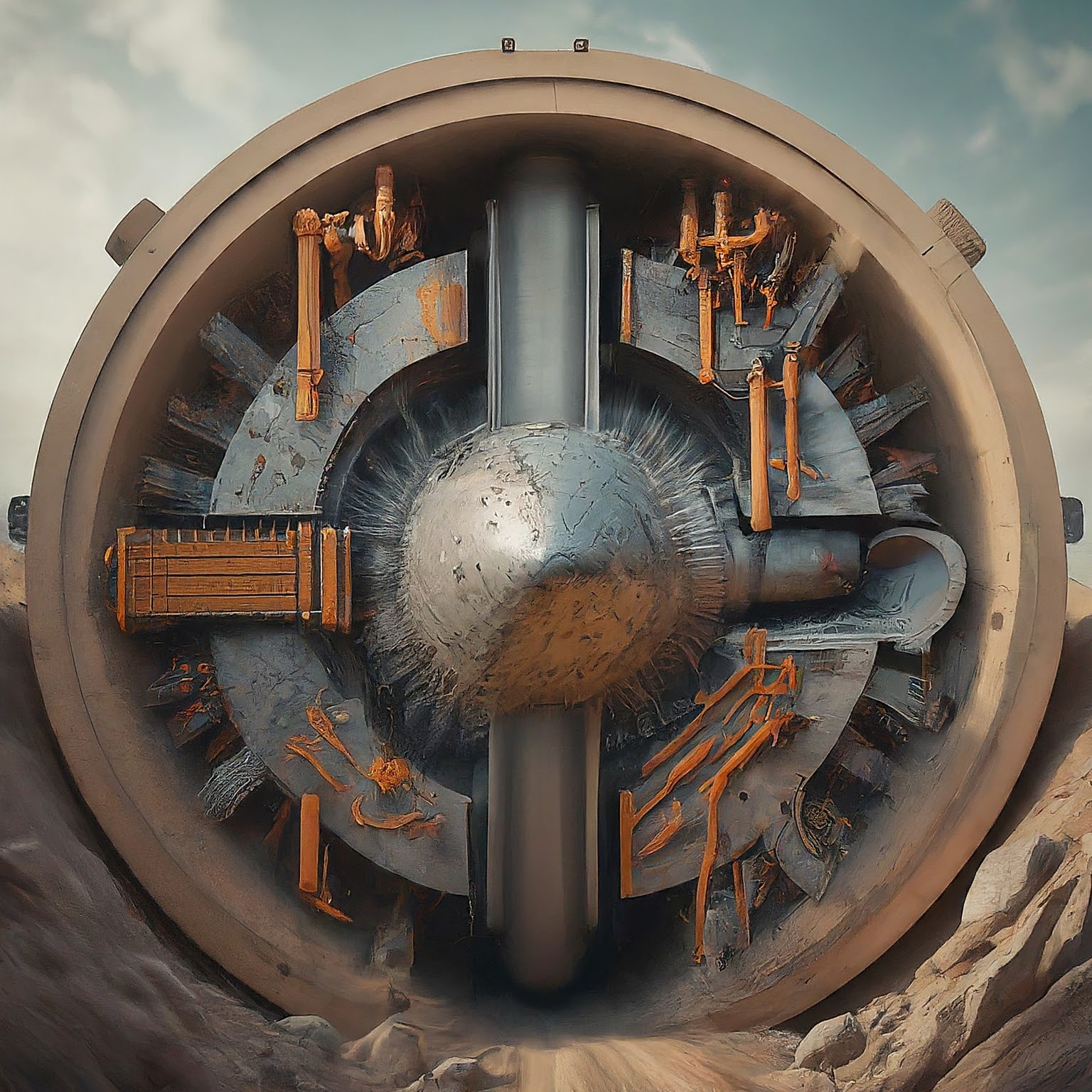

Imagine a giant, mechanical version of a cheese grater, only instead of cheese, it munches its way through rock and soil. That’s essentially the core function of a TBM’s cutting head. This massive disc, equipped with rows of sharp teeth or disc cutters, rotates at high speeds, grinding and breaking down the earth as the TBM advances.

The specific design of the cutting head depends on the type of ground the TBM is encountering. For softer soils, single disc cutters might suffice. However, for tougher terrain like hard rock, a gripper head with powerful teeth is used to pulverize the material.

Keeping Things Tidy: The Muck Removal System

Just like we wouldn’t want crumbs scattered everywhere after making a sandwich, TBMs have a clever system to keep the tunnel clean as they chomp their way forward. Behind the cutting head lies a sophisticated muck removal system. This typically consists of a conveyor belt that continuously scoops up the broken rock and soil, transporting it away from the excavation face.

Depending on the project’s needs, the removed material (also known as “muck”) can be disposed of in various ways. Sometimes, it’s hauled away by trucks and used for construction projects elsewhere. In other instances, the muck might be transported via a conveyor belt system to a processing facility on the surface.

Building Block by Block: Constructing the Tunnel Walls

As the TBM excavates its path forward, it doesn’t simply leave an empty void behind. To ensure the stability and safety of the tunnel, TBMs act like giant Lego builders, simultaneously constructing the tunnel walls as they move. This is achieved through the use of pre-fabricated concrete segments. These segments, typically hexagonal or circular in shape, are brought in on a separate conveyor belt and meticulously fitted together using a specialized segment erector.

The segments act like a giant lining, holding the surrounding earth in place and preventing cave-ins. The specific design and thickness of the segments will vary depending on the size of the tunnel, the ground conditions, and the intended use of the tunnel.

The Great Push Forward: How TBMs Move Underground

So, how does this chomping machine manage to move forward after it’s done excavating a section of the tunnel? TBMs utilize a powerful system of hydraulic jacks. These jacks are strategically positioned against the newly installed concrete segments, pushing the entire machine forward with tremendous force. It’s a slow and methodical process, but it allows the TBM to steadily inch its way through the earth, leaving behind a completed tunnel in its wake.

The entire tunneling operation is monitored and controlled from a central command center within the TBM. Here, a team of highly skilled engineers oversees the machine’s functions, constantly adjusting parameters like cutting head rotation speed, thrust force from the hydraulic jacks, and muck removal rate.

A World of Applications: Where TBMs Are Used

TBMs are incredibly versatile machines and are used in a wide range of underground construction projects. Here are some of the most common applications:

- Urban Transportation: TBMs are instrumental in creating the intricate networks of subway tunnels that form the backbone of public transportation systems in major cities around the world.

- High-Speed Rail Lines: The construction of high-speed rail lines often relies on TBMs to efficiently carve out long, straight tunnels that minimize travel time.

- Water and Wastewater Tunnels: Large diameter TBMs are used to create tunnels for water canals, critical for transporting water resources and managing wastewater disposal in urban areas.

- Utility Tunnels: These tunnels house essential utilities like power lines, communication cables, and sewage pipes. TBMs can be employed to create these tunnels with minimal disruption to the surface environment.

- Road Tunnels: In mountainous regions or densely populated areas, TBMs can be used to construct road tunnels that provide safe and efficient passage for vehicles.

- Hydropower Projects: Tunnels are often a crucial component of hydropower projects, diverting water to generate electricity. TBMs can be eingesetzt (German for “deployed”) to create these tunnels through rock and soil.

Tunneling Through Challenges: Advantages of TBMs

Compared to traditional tunneling methods that rely on explosives or manual labor, TBMs offer several significant advantages:

- Efficiency: TBMs are incredibly efficient at excavating tunnels. Their continuous cutting and muck removal process allows for rapid progress, significantly reducing project timelines.

- Safety: TBMs minimize the risks associated with traditional tunneling methods. Workers are shielded from the excavation face, reducing the chance of accidents. Additionally, TBMs generate less dust and debris, improving air quality within the tunnel environment.

- Accuracy: These machines can operate with remarkable precision, ensuring that tunnels are excavated to the exact specifications. This reduces the need for additional excavation or reinforcement work later.

- Reduced Environmental Impact: Because TBMs operate within a closed excavation environment, they generate minimal noise and dust pollution on the surface. Additionally, they can be used to create tunnels with minimal disruption to existing infrastructure and surrounding ecosystems.

Supersize Me: The Immensity of TBMs

TBMs come in a variety of sizes, but they are all undeniably colossal machines. Some TBMs can be as wide as a four-lane highway and long enough to stretch the length of a football field! These behemoths can weigh millions of pounds and are truly marvels of modern engineering.

The size of a TBM is determined by the diameter of the tunnel it needs to create. Large-scale projects, such as high-speed rail lines or water canals, often require massive TBMs. Conversely, smaller diameter TBMs might be used for utility tunnels or pedestrian walkways.

Tunneling into the Future: Advancements in TBM Technology

TBM technology is constantly evolving, with engineers developing even more sophisticated and efficient machines. Here are some exciting advancements on the horizon:

- Autonomous TBMs: Research is underway to create fully autonomous TBMs that can operate with minimal human intervention. This would further enhance safety and efficiency in tunnel construction projects.

- Environmentally-Friendly Designs: The development of TBMs that utilize electric or hybrid power sources is gaining traction. This would significantly reduce the environmental impact of tunnel construction.

- Real-Time Monitoring Systems: Advanced sensor technology is being integrated into TBMs to allow for real-time monitoring of ground conditions and machine performance. This data can be used to optimize tunneling operations and ensure the safety of workers.

The Amazing World of Tunneling: Conclusion

The next time you zip through a tunnel on your way to work or school, take a moment to appreciate the incredible feat of engineering that made it possible. TBMs, these remarkable machines, have revolutionized the way we build tunnels, creating efficient and safe transportation networks, utility corridors, and infrastructure projects around the world.

As technology continues to advance, TBMs will undoubtedly play an even greater role in shaping the future of underground construction. So, the next time you hear the rumble of a train or see the lights of a subway disappear into the darkness of a tunnel, remember the mighty TBM – the unsung hero silently carving its way through the earth!