Introduction

The realm of optical device manufacturing stands as a cornerstone in various industries, driving innovations in communication, healthcare, consumer electronics, and beyond. The evolution of these devices, from intricate lenses to sophisticated sensors and beyond, has revolutionized our capabilities. However, the journey to scale manufacturing in this domain is riddled with challenges, necessitating inventive solutions to streamline production processes.

The Landscape of Optical Device Manufacturing

Evolution and Importance

Optical devices have traversed a remarkable evolution, evolving from basic lenses to complex systems encompassing lasers, sensors, and imaging components. Their significance in modern technology is irrefutable, forming the backbone of cutting-edge advancements in fields like medical diagnostics, telecommunications, and augmented reality.

Market Demands and Scaling Challenges

The burgeoning demands for optical devices, driven by the exponential growth of technology applications, present a dual challenge. On one hand, meeting market demands at scale; on the other, ensuring consistency and precision in production. Scaling up manufacturing processes while maintaining quality standards remains a formidable obstacle.

Key Challenges in Scaling Optical Device Manufacturing

Precision and Quality Assurance

The very essence of optical devices lies in their precision. Achieving the required levels of precision consistently, especially during high-volume production, poses a significant challenge. Even the slightest deviation can impact the functionality and performance of these devices. Implementing stringent quality control measures and advanced testing methodologies becomes imperative to ensure adherence to specifications.

Material Selection and Sourcing

Selecting the right materials is pivotal in manufacturing high-quality optical devices. However, the scarcity or inconsistency in sourcing these materials poses a hurdle. Ensuring a consistent supply chain for specialized materials demands strategic partnerships and proactive contingency plans to mitigate potential disruptions.

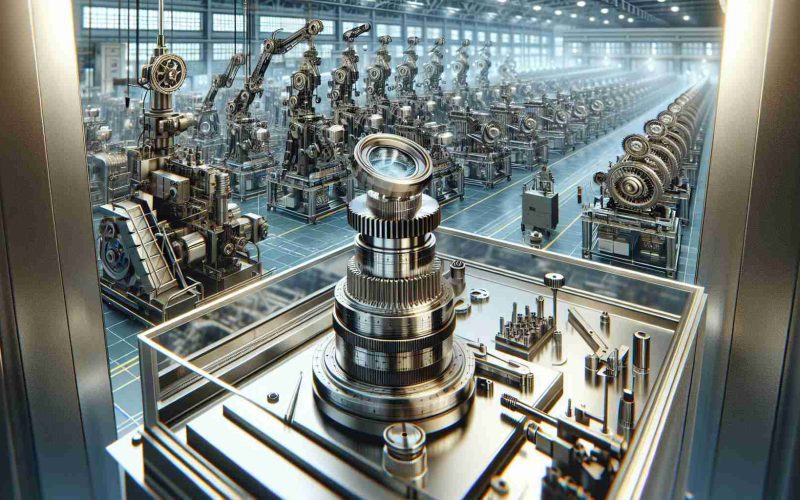

Complexity in Manufacturing Processes

The intricate nature of optical devices necessitates complex manufacturing processes. From lens polishing to intricate assembly and calibration, each step requires meticulous attention. Scaling these processes without compromising precision and efficiency is a considerable challenge, often requiring innovative automation and advanced robotics.

Innovative Solutions and Strategies

Advanced Automation and Robotics

Integrating advanced automation and robotics into manufacturing processes can significantly enhance efficiency and precision. Robotics capable of intricate handling and assembly tasks coupled with AI-driven quality control systems minimize errors and accelerate production without compromising on accuracy.

Material Science and Research Collaboration

Investing in research and collaborations in material science is crucial. Developing alternative materials or refining existing ones to ensure consistency and quality in production helps mitigate supply chain vulnerabilities. Collaborations with research institutions foster innovation in materials and manufacturing techniques.

Data-Driven Optimization

Leveraging data analytics and machine learning enables predictive maintenance, process optimization, and real-time monitoring. Implementing sensors and data collection devices throughout the manufacturing line provides insights for continuous improvement, reducing defects and enhancing overall yield.

The Road Ahead

The future of optical device manufacturing lies in the convergence of innovation and collaboration. Advancements in technology, coupled with strategic partnerships and a relentless pursuit of precision, will define success in scaling production. Embracing challenges as opportunities for innovation will propel the industry towards greater heights.

Conclusion

Scaling optical device manufacturing requires a delicate balance between precision, innovation, and scalability. Overcoming challenges in materials, processes, and quality demands a concerted effort across the industry. By integrating advanced technologies, fostering research collaborations, and adopting data-driven strategies, the landscape of optical device manufacturing can evolve, meeting burgeoning demands while maintaining the highest standards of quality and precision. As the industry continues to evolve, the path to seamless scaling of optical device manufacturing lies in the synergy between technological advancements and a commitment to precision, ensuring that these pivotal devices continue to empower and transform the world as we know it.